Central Workshop

Workshop is the central facility for imparting training to the students of all branches of 1st Year B.Tech. in various shops. Training is also imparted to Mechanical Engineering students, in the subject of Manufacturing Process. Central workshop comprises various shop namely CNC Shop, Fitting Shop, Welding Shop, Sheet metal Shop, Carpentry Shop, Pattern making Shop, Smithy Shop, Foundry Shop, Turning Shop, Machine Shop and Fabrication Shop. Students of all branches use workshop facilities for fabrication of their minor and major projects. These shops are well equipped with latest tools, equipments and machineries for carrying out research work at M.Tech. and Ph.D. level in the area of manufacturing engineering with specialization in Metal Cutting and Casting.

| Functionaries | ||||

| Sl. No. | Name | Responsibility | Phone No. | |

|---|---|---|---|---|

| 1 | Dr. Sant Ram Chauhan | Faculty Incharge, Associate Professor | 254734, 254760 | ficcwshop@nith.ac.in View Profile |

| Officers | ||||

| Sl. No. | Name | Designation | Phone No. | |

| 1 | Dr. Amarjit Singh | Scientific Officer/Technical Officer, Officer-in-Charge (OIC), Central Workshop | 254762 | oiccwshop@nith.ac.in View Profile |

| Technical Staff | ||||

| Sl. No. | Name | Designation | Phone No. | |

|---|---|---|---|---|

| 1 | Sh. Ravinder Kumar | Technical Assistant SG-I | 254767 | ravinderkumar@gmail.com |

| 2 | Sh. Inder Singh Guleria | Technical Assistant SG-I | 254766 | isg@nith.ac.in |

| 3 | Sh. Avinash Agarwal | Technical Assistant SG-II | 254764 | avinashagarwal1979@gmail.com |

| 4 | Sh. Santosh Kumar | Technical Assistant SG-II | 254768 | sunny10april@nith.ac.in |

| 5 | Sh. Sunil Kumar | Technician SG-II | 254771 | sunilkumar@nith.ac.in |

| 6 | Sh. Santosh Kumar Yadava | Technician SG-II | 254777 | skyadav@nith.ac.in |

| 7 | Sh. Kishore Chand | Technician SG-II | 254778 | kishorechand@nith.ac.in |

| 8 | Sh. Vijay Kumar | Sr. Technician | 254774 | vksnitham@gmail.com |

| 9 | Sh. Saleem Mohammad | Sr. Technician | 254772 | saleem@nith.ac.in |

| Central Workshop Staff | ||||

| Sl. No. | Name | Designation | Phone No. | |

| 1. | Sh. Ravi Das | Junior Assistant | -- | ravidas@nith.ac.in |

| 2. | Smt. Salochana Kumari | Sr. Office Attendant SG-I | 254772 | devisalochna00@gmail.com |

| Activities | |||

| Sl. No. | Workshop/STTP | Organizing Deptt/ Central Workshop | Date |

|---|---|---|---|

| Short Term Training Programme on “Advances in Machining Processes” | Central Workshop | 19th – 23rd Feb, 2018 | |

| Short Term Training Programme on “Quality Management Systems (QMS) issues tools and Implementation”. | MED | 10th – 14th July, 2015 | |

| STTP on Advance Welding Processes for ITI Instructors on Machinist/Tool & Die Maker | Central Workshop | 7th - 12th July, 2014 | |

| Short Term Training Programme for ITI Instructors on Fitter/Turner | Central Workshop | 30th June,2014- 5th July, 2014 | |

| Application of Power Operated Tool (Metal Cutting & Wood Working) | Central Workshop | 5th -9th July, 2010 | |

| Repair and Maintenance of Wood and Steel Furniture | Central Workshop | 14th -18th Dec, 2009 | |

| Workshop for Entrepreneurship on Self Employment in Technical Field | Central Workshop | 24th Feb, 2007 | |

| Application of Forging Processe | Central Workshop | 19th-23rd Dec, 2006 | |

| Use of Power Operated Tools in Metal Working | Central Workshop | 11th -15th Dec, 2006 | |

| Plumbing and Pipe Fitting | Central Workshop | 22nd – 26th May, 2006 | |

| Awareness Workshop for Panchayat Pradhans | Community Services | 28th Apr, 2006 | |

| Workshop on Use of Power Operated Hand Tools | Central Workshop | 25th -26th Mar, 2006 | |

| Machining Processes | Central Workshop | 16th – 20th Dec, 2005 | |

| Awareness Workshop on Services to Community | Central Workshop | 25th – 30th May, 2005 | |

| Application of Wood Working Machining Processes | Central Workshop | 16th – 20th May, 2005 | |

| Welding Processes (Arc & Gas Welding) | Central Workshop | 20th & 24th Dec, 2004 | |

CNC Shop

- Training as well as research work is being carried out in CNC shop for B.Tech. and M. Tech/PhD respectively. The list of Major Machines / Equipments are as follows.

- CNC Train Master

- VMC Train Master

- CNC Turning Centre

- CNC Machining Centre

- Computers with AUTO CAD facility

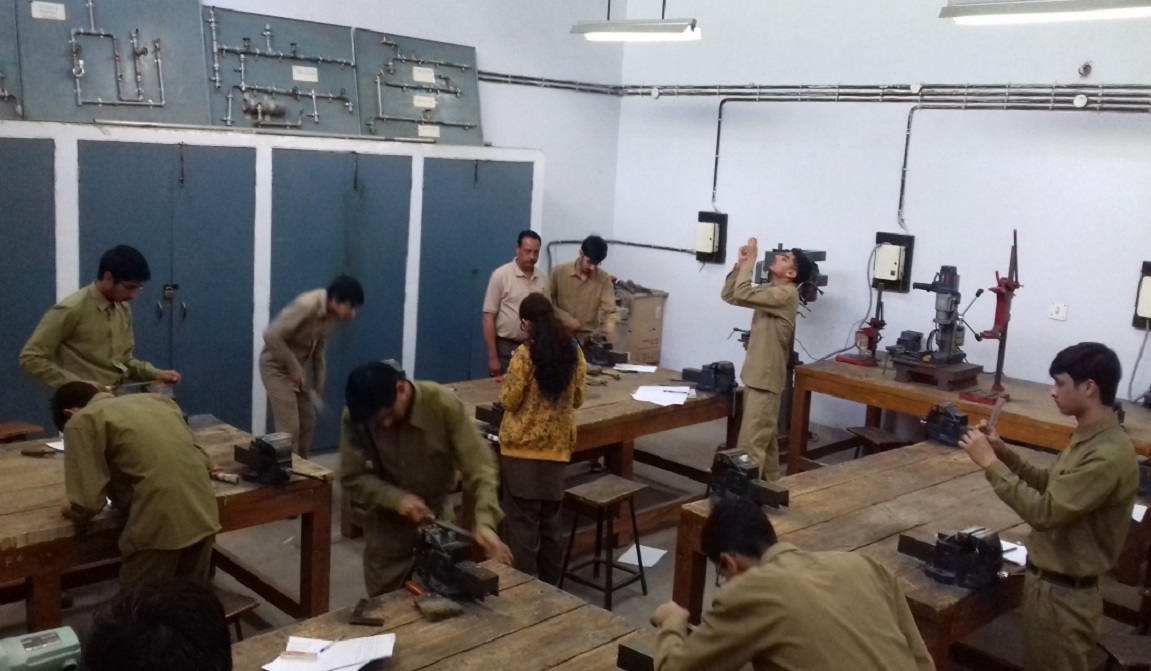

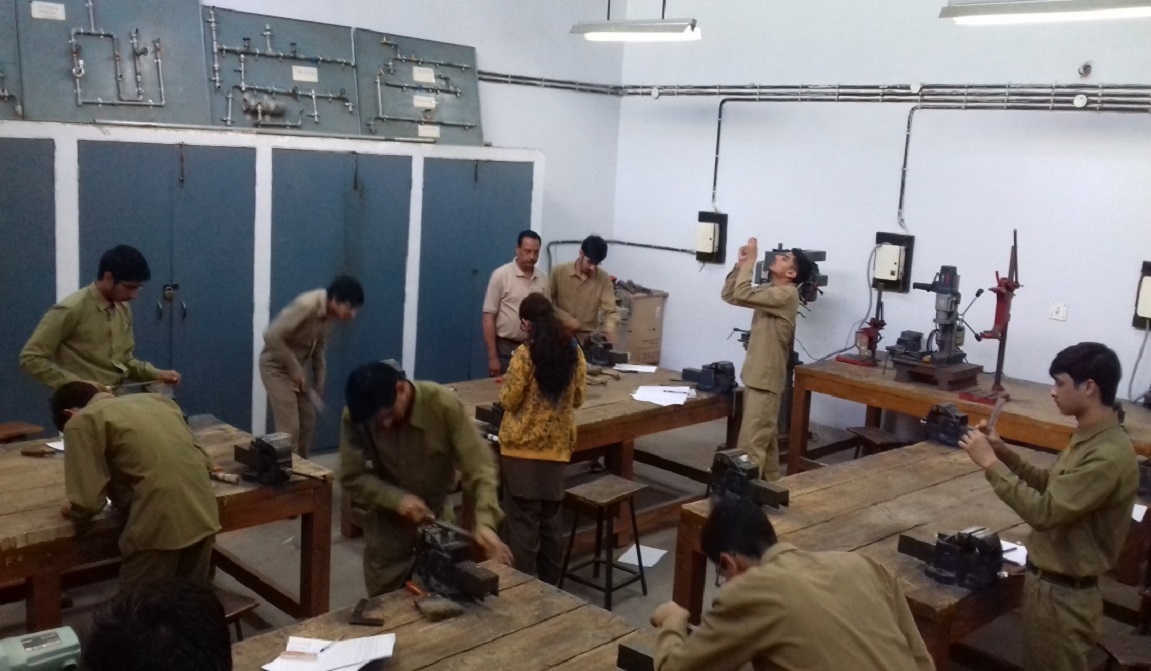

Fitting Shop

- Practices as well as projects are undertaken for B.Tech /M.Tech and PhD students. The list of Major Machines/Equipments are as follows:

- Various types of hands and power operated tools like Jig Saw, Saber Saw, Impact Wrench, Cordless Screw Driver, Tapper, High Speed Cut Off Saw

- Pedestal Grinder & Bench Grinder

- Upright Drilling Machine with tapping facility

- Power Hacksaw Machine

- Pedestal Drilling Machine

Welding Shop

- Welding shop is developed keeping in view the requirements of the industry. Practice on latest and traditional welding techniques is also undertaken. The list of Major Machines/Equipments are as follows:

- Welding Transformers / Welding Machine

- Plasma Cutting Machine

- PLC Based Spot cum Projection Welding Machine

- PLC Based Longitudinal Seam Welding Machine

- Brazing Machine

- High & Low Pressure Gas Welding Equipment

- Drilling and Tapping Machine

- Bench Grinding Machine

- Horizontal Metal Cutting Band Saw

Sheet Metal Shop

- Practice of different sheet metal operation is carried out by using traditional and modern hand tools and power operated tools. The fabrication of projects is also undertaken by the students.

- Spinning Lathe

- Power operated tools like Nibbling & Shearing Machine

- Power Press

- Air Compressor facility for Painting

- Hydraulic Press

- Toggle Press

- Riveting, Notching & Punching Machine

- Edge Bending Machine

- Burring Machine

- Sheet Bending Machine

- Pipe Bending Machine.

- Foot Operated Shearing Machine

The list of Major Machines/Equipments are as follows:

Carpentry & Pattern Making Shop

- Basics of wood working and pattern making are being imparted to the B.Tech students. The traditional as well as advanced (power operated) tools and machine are available for updating the knowledge on the students in this field. The list of Major Machines/Equipments are as follows:

- Vertical Band Saw Machine

- Universal Wood Working Machine

- Pattern Making Lathe

- Combined Surface & Thickness Planner

- Four Side Planner

- Hammer Drill

- Chain Saw

- Various Power operated tools

- Wood Working Lathe Machine

- Spindle Molding Machine

Smithy Shop

- Basic knowledge and practice of various smithy and Forging operations is imparted to the B.Tech Students. The list of Major Machines/Equipments are as follows:

- Open Hearth Furnaces

- Induction Heating Furnace

- Pneumatic Power Hammer

- Spring Hammer

- High Speed Cut Off Saw

- Smithy Tool Kit

Foundry Shop

- Green Sand Moulding, Molasses Sand Moulding facilities and sand testing facilities are being created to impart practical training to the students of B.Tech and to carryout M. Tech/PhD research work on induction melting furnance by using stir casting. The list of Major Machines/Equipments are as follows:

- Mini Couple Furnace

- Oil Fired Tilting Furnace

- Induction Heating and Melting Furnace

- Pit Furnace

- Hydro-Pneumatic Molding Machine

- Universal Sand Testing Machine

- Sand Muller & Sand Mixture

- Permeability Meter

- Foundry Tool Kit

Turning Shop

- All gear head lathe machines with different Specifications, Attachements and accessories Like DRO, Copping, Taper Turing and turret Etc are available for basic training to the B.Tech. students and for major/minor projects to M.Tech/PhD research work . The list of Major Machines / Equipment are as follows:

- Lathes

- Production Lathe

- Drilling Machine

- Power Hacksaw

- Pedestal Grinder & Bench Grinder

Machine Shop

- Facilities like Milling, Grinding, Gear Hobbing, Shaping, Planing and Sloting to impart practical skills to the B.Tech Students as well as to carry out the Research Work are provided. The list of Major Machines/Equipments is as follows:

- Universal Milling Machine

- Ram Turret Milling Machine

- Radial Drilling Machine

- Gear Hobbing Machine

- Shaper / Planner Machines

- Hydraulic Surface Grinder

- Universal Tool Cutter & Grinder

- Slotter Machine

Fabrication Shop

- Fabrication shop has been developed to provide extra fabrication facility for Major/Minor projects of the students without disturbing the routine classes. The Fabrication shop being utilized by UG / PG / Ph.D students for fabrication of their major and minor projects. The list of Major Machines/Equipment is as follows:

- Portable Welding Machine

- High Speed Cut Off saw

- Bosch Power Operated Tool Kit

- Heavy Duty Jig Saw

- Power Drill

- Angle grinder

- Saber saw

- Hot air gun

- Shearing Machine

Dr. Sant Ram Chauhan

Faculty In Charge

Central Workshop

National Institute of Technology Hamirpur

Himachal Pradesh, PIN 177005, India

Phone No. : 01972-254760, 254734

Email : ficcwshop@nith.ac.in